OOK-Press Printing House

Quality solutions in the field of offline communication.

We are your partner in implementation! Request a personalized quote from our colleagues! offset, digitális, széles formátumú, grafikai területen

Printing Execution

Comprehensive printing services in the printing industry for 30 years!

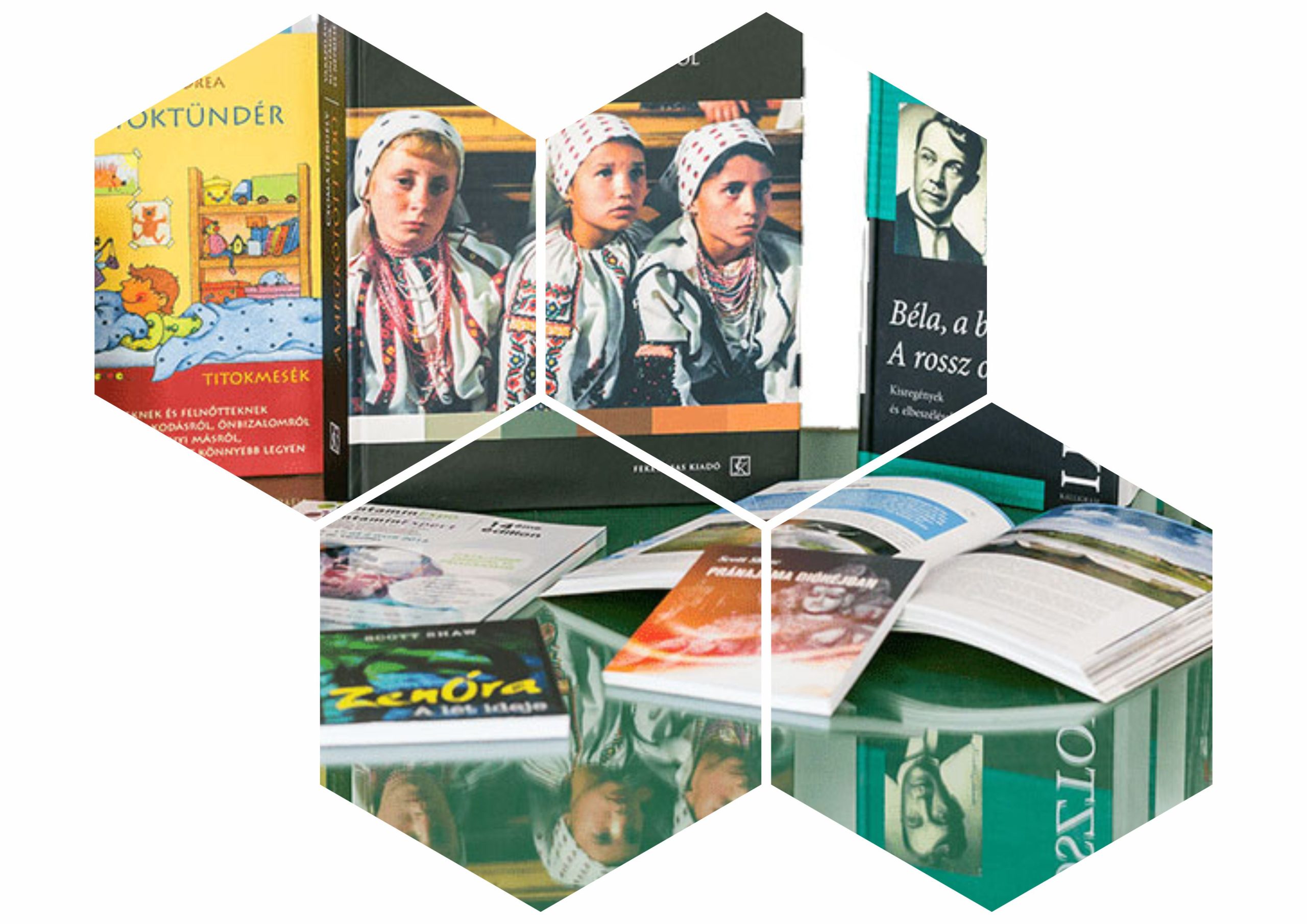

Hardcover Book

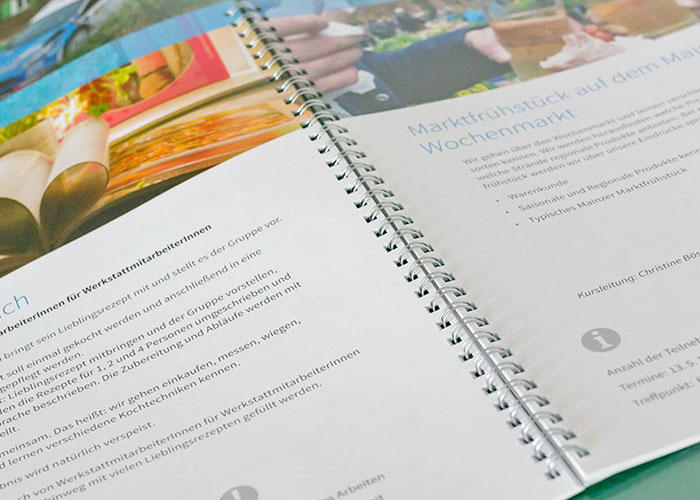

Saddle-Stitched Notebook

Board Printing

Banner Printing

Glass Panel Printing

Cardboard Furniture

Photo Frame Printing

Contact us, let's get started together!

Printing execution in excellent quality.

We are fortunate to live from what we love. We are innovative and entrepreneurial. We operate across a wide spectrum. We have already helped numerous companies and individuals design and realize their visions, and we consider your inquiry a matter close to our hearts! We are at your service, from planning to implementation.

Outstanding quality printed products.

We are your partners in realization! Request a personalized quote from our colleagues! Quality and excellence for satisfied customers!

- Books, encyclopedias.

- Notebooks, newspapers, brochures.

- Flyers, leaflets, posters.

- Business cards, letterheads, notepads.

- Document holders, folders, envelopes.

- Family books, calendars, wedding materials.

- Printed decorative films for vehicles, business, office, and personal use.

- UV flatbed printing on various materials.

- Banner, roll-up, building mesh, press wall.

- Canvas-printed and stretched images.

- Posters, signs, wallpapers, printing on acrylic, wood.

About us!

Our printing services.

Expertise and attentive care. This is what we bring to even the smallest order. Along with cutting-edge technology, we also offer practical knowledge and human support. Because a satisfied customer counts double.

Important information.

Contact

- +36 (88) 425 260

- info@ookpress.hu

- 8200 Veszprém, Pápai Road 37/A.

Flyer Printing